Olney, TX – After many years of working with the Federal Aviation Administration and expert engineering consultants, Air Tractor announced in September the conclusion of its AT-502 series wing fatigue test program. The FAA has approved a safe life of 9,800 hours, with no inspections required, for the p/n 21058 replacement spar cap installed in AT-502/502A/502B aircraft since May, 2004 and for new production aircraft starting with s/n 502B-0702 manufactured in September, 2004.

This test began in March 2005, with a computer-controlled test rig running day and night, seven days a week applying realistic working loads to an Air Tractor AT-502 wing. The five-month test concluded in September after the wing had accumulated more than 41,000 flight hours. After calculating the required “scatter factor” that accounts for material variations and different operating environments, the 9,800 hour safe life was FAA approved. This equates to approximately 20 years of service in a typical operation before any major wing modifications are required.

During the test no cracks were found in the spar caps at the center splice wing connection, reports Jim Hirsch, V.P. of Engineering at Air Tractor. “The crack that occurred was outboard of the wing attach angles, in the second fatigue-critical location. Then at 41,364 hours we found a crack in one of the wing attach blocks and terminated the test. These results confirm our belief that one part of the safest fatigue management solution is to retire fatigue-critical components.”

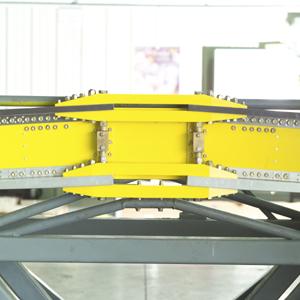

The fatigue test setup consisted of two full-scale wings mounted upside down in a movable fixture. A heavy brace supported one wing, while a hydraulic cylinder applied computer-controlled loads to the other wing. The loads applied had been previously recorded from an instrumented AT-502B during actual spraying operations.

“We are not aware of any other agricultural aircraft manufacturer that has a program as comprehensive as that of Air Tractor,” says Hirsch. “As our wing fatigue testing program progresses, operators will know that their Air Tractor aircraft have a standard of airworthiness that is second to none in our industry.”

“We have learned a lot since our first fatigue testing program began more than ten years ago,” comments Hirsch. “We’ve made changes to the center splice design and manufacturing process which we’ve found to improve the fatigue characteristics of the wings. One of these improvements is cold-working of the outboard bolt holes.”

“Pilot safety and protection has been a key priority in Air Tractor aircraft design since Leland Snow built the first Air Tractor. Our full-scale fatigue testing program is another way we are working to provide a higher level of confidence for our customers,” says Hirsch.

Air Tractor owners with aircraft built prior to 502B-0702 or who had spar cap replacements prior to May, 2004 should contact Gene Williams, Air Tractor’s Customer Service Manager, for details about cold-working and the safe life for their specific aircraft configuration.