Smooth Operator.

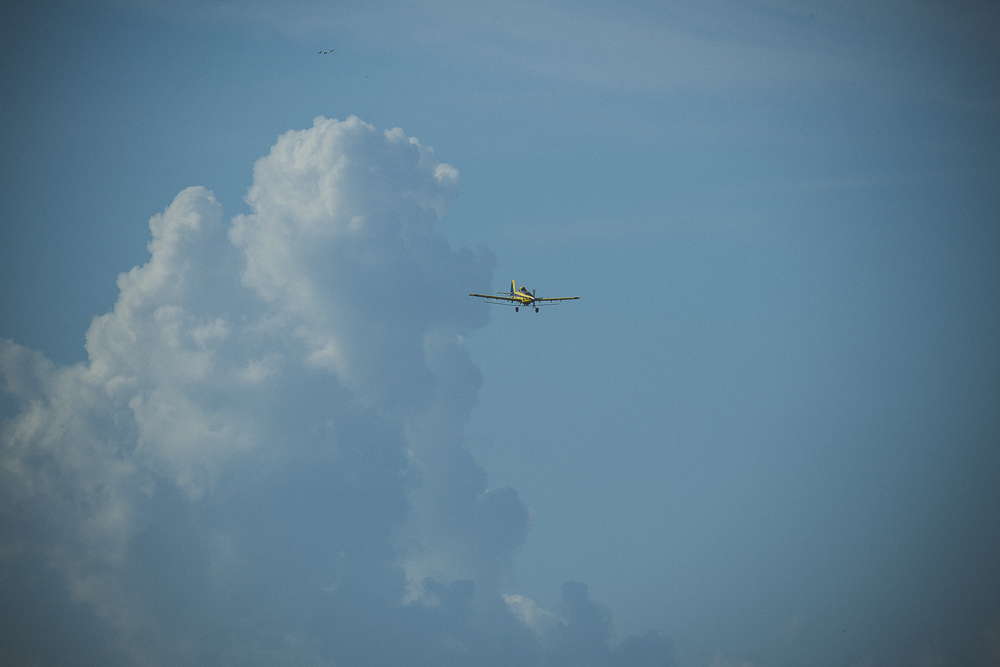

Dwayne O’Brien, Owner-Operator | O’Brien Flying Service, Iowa LA | 502XP

For Dwayne O’Brien, slow is smooth. Smooth is fast. It’s how he produces results for his customers.

Having hunted Osama Bin Laden in Afghanistan as a helicopter pilot in the US Army, Dwayne O’Brien knows the value of tempo, agility and persistence. These qualities have served him well as an ag operator, too. However, in order to run an operation profitably and safely—season after season, priorities have evolved. Reliability, stability and trust is what drives his ag operation. And Dwayne appreciates those same qualities in his relationship with Air Tractor.

Dwayne leads O’Brien Flying Service in Iowa, Louisiana. Started by his father, Zoren, the ag flying service has been in operation since 1972.

“I guess I am the ringmaster here,” Dwayne jokes. “We run four aircraft, and we’ve got 17 people that work here – including mechanics, pilots, loaders, truck drivers and office personnel.”

Dwayne’s operation, located just a few minutes drive east of Lake Charles, is primarily focused on rice, but they also spray soybean, sugarcane and pasture land. Sounds like a typical South Louisiana aerial spraying business, but O’Brien Flying Services has diversified its portfolio.

“We’re not a one dimensional operation at all,” Dwayne explains. “I think we get into a lot more different kinds of work than others in this area. We do pipeline right-of-way work. We’ll spray duck ponds, bayou boat trails, alligator trap trails, fence rows, and a good bit of brush work.”

O’Brien says he’s even searched for lost cattle. “We’ve helped law enforcement chase down high speed motorcycles and cars when they can’t keep up. We’ve dropped water on fires when the parts of the town have caught fire. We do a lot for our local community.”

Powering a diverse operation

An ag spraying service that keeps busy year round has to be built upon a solid foundation. For years, O’Brien Flying Service operated Ag Cats, before recently moving up in capacity and performance to the Air Tractor 502XP.

With extra power to haul a full load even on the hottest humid days, the Air Tractor 502XP is ideally suited for the high density altitude conditions of South Louisiana.

“The biggest thing around here is power. As a pilot, you can feel when you’re overloaded and flying right on that edge of the power spectrum,” Dwayne explains. “We’ve got short strips, and probably 55 or 56 remote strips that we work off of other than our FOB here in Iowa. The 502XP has no problem taking off from those strips that were originally built for other aircraft. And with the XP, we can carry that same payload if not more so than the Ag Cat.”

With its capacity and power, the 502XP has what it takes to get a wide variety of jobs done.

“I just want to have the best equipment, the best people and to do the best job that I can,” Dwayne says.

“I like the productivity. I like the efficiency of the 502XP. It’s a nice, new platform. I wish we had them 10 or 15 years ago. All the pilots, whether they’re young or old, who currently fly the XP say it’s probably the best machine they’ve flown.”

Daredevil tamed

The level-headed ag operator of today is a far cry from the youngster growing up in these fields.

“I guess as a kid growing up around here, we all were kinda daredevils,” he says. Dwayne raced motorbikes and go carts. Raised by a pilot, it wasn’t much of a surprise that he would be drawn to the adrenaline rush of flying.

“Because my father was a pilot, I was always around pilots. I took that sense of thrill and speed from my ground pursuits to the air,” Dwayne says. “I grew up around World War II era pilots who taught me how to fly. Those guys passed on their techniques to me. It was really good hangar talk—having this pool of pilots who could pass on the thing that they’re best at.”

Dwayne learned something from each of them. And it shaped the young kid into the well-rounded aviator that he is today.

“Now it’s our turn to pass it down to the next generation of pilots,” he says.

Charting his path

Before taking over as owner-operator, Dwayne was exposed to every facet of the aerial application business. “I grew up here as a mechanic’s helper. When I got older, I became a truck driver. I worked as a loader. I cleaned bathrooms and swept floors. I’ve done every job that’s out here.”

Dwayne eventually became a line pilot. Then he left the operation to attend college. A load of books was not going to keep him grounded, though.

“I was going through law school, and I learned that I didn’t really care to be an inside guy looking at the world outside,” Dwayne says.

So Dwayne signed up for the Reserve Officers Training Corps – with the objective to fly. Dwayne moved through ROTC and right into the Army, spending the next several years flying helicopters in hot spots around the world.

“I walked right into a command, right into the first Gulf War, and spent about six years getting my mail at Fort Bragg. But I really didn’t stay there a lot. My unit stayed deployed quite a bit.” Missions to Somalia and other conflict zones followed. Then the operation at home started calling.

“My dad was getting older. He was getting ready to retire, so he said, ‘Here’s your opportunity. If you come home now, then I can teach you how run this business. Otherwise, who knows if I’m gonna be around long enough to physically show you?’”

His father had recently gone through heart surgery. “Dad knew that his time was getting short,” Dwayne recalls.

Dwayne remained in the military as an Army Reservist, but began working at home, too. For a while he had a foot in both worlds.

Then 9/11 happened.

“I was spraying beans that morning. We came in and watched what was happening on TV. When that kind of thing happens, as a reservist, you know you might get called up. With the unit I was in, I was almost certain I would.” Dwayne didn’t have to wonder very long.

“By October 10, we were already conducting operations in and around areas of Afghanistan, flying out of Uzbekistan to the north.” Serving his country came first; his permanent return to Louisiana would have to to wait.

From combat pilot to ag operator

Following Dwayne’s post-9/11 deployments, he returned home and assumed the helm of the operation. He felt he was ready.

Having the right mentors along the way had prepared him for this day.

“It was all those older WWII pilots who taught me the ropes as a young man. There were maintenance-oriented pilots, and guys who were stunt pilots – they were all here working for Dad. Those guys had tens of thousands of ag flying hours between them.

One of his most influential mentors was a guy named Roy “Pappy” Crandall, a World War II Naval Aviator.

“I never recall Pappy talking bad about anybody. He always wore long sleeved shirts. And when he flew, he wouldn’t be pulling power, but you could never catch the guy. He was fast because he knew how to get the best out of an airplane. I would fly all day with him and come back just wore out, sweaty and tired—at just 30 years old! And there was Pappy, a guy in his 70’s who could still fly circles around me.”

You just had to suck it up and keep going.

“Pappy never really complained. He just pressed on. For all of us pilots who grew up together here, that was good for us to learn.”

Lessons learned

As he made the transition from a line pilot to being the boss, Dwayne quickly realized there was a whole lot of other stuff to think about.

“You can’t multitask much and still be safe,” he says.

Sitting behind a desk as an owner-operator, you deal with the minor and major emergencies on the ground, and while sitting in your ag plane you make sure you protect the plane and your own neck.

“I would be up there watching out for a wire then suddenly realize that I’d already flown past it! How did I miss it? I don’t know. But that made me realize it’s really hard to do both jobs well. When I would land, farmers were waiting in the office to talk to me, along with whatever issues had happened in the last 20 minutes while I was putting out a load. This truck’s broke, that truck may be stuck, this farmer’s late… What do we do? What do we do?” Dwayne says.

One day, he made an executive decision: “I realized that I good enough pilots and people here. Instead of cutting the pie seven ways or six ways because we had seven aircraft at the time, I decided we would just go with six. I would keep my airplane as a spare and fly only as necessary or on the weekends.”

And that’s when I knew I had become an operator.

Good people, good gear

When it comes to running a successful aerial spraying operation, two things matter the most: reliable aircraft – and good people to operate them.

“The key is having the right people representing you and your company – be it at the pilot level, the loader level, or the maintenance level. They carry the flag of your business. So you’ve gotta have good people in those positions—people you rely on to represent and do things for your company, the safe way, the right way, and the efficient way,” Dwayne explains.

Trust matters – especially if your operation runs multiple aircraft.

“Because there’s no way you can be in multiple places at one time, you’ve gotta have quality people doing the job.”

Dwayne has had good luck with the homegrown crowd.

“Kids who have been in FFA, who have done woodworking and welding. They’ve been around equipment. They understand safety with their hands. They know if it looks dangerous, it looks like it may bite, they don’t touch it, and ask for help. These kids who work on the ground crew straight out of high school or while in college, they come back and work for us four to five seasons until they get their first jobs,” he says.

Sometimes they come back a few years later. They appreciate all they learned at O’Brien Flying Service, and the values instilled upon them, Dwayne feels good about that. “There are quality people here, and quality people everywhere. But you must take the effort to find them, train them and retain them.”

Taking it to the next level

Armed with the values he learned from the old timers, Dwayne paired them with lessons learned in the military and updated his equipment to grow O’Brien Flying Service into an ag operation with an eye on the future.

“I like technology. It’s what makes America great. It’s what makes aviation great. That’s why we are one of the leading countries in the world,” Dwayne says.

Technology allows operations and pilots to work efficiently, effectively and more safely.

The American Way

Despite the challenges of ag aviation and the daily demands of the job, he feels it’s still one of the best jobs out there. And Dwayne is looking forward to the next generation making the industry their own.

“I see younger people who want instant gratification. But here in this business, it takes time. We take a crawl-walk-run approach when training new pilots, and we’ve trained a lot of new pilots here,” he says.

Training young pilots is something Dwayne enjoys. He has them do mostly dry work before they get to do spray jobs.

“One thing I can say, especially in this business, is just be patient. Persistence and patience—but mainly patience. It will come in time, if you just hang in there,” he says.

Dwayne expects this sort of persistence from those working for him.

“My philosophy is ‘don’t tell me that you can’t do something. Tell me how you’re gonna.’ Because it can happen and it will happen. That’s the American way. It’s what makes America great. We’re not a society of people that ever say no. For anything that’s ever presented a problem, there’s the American Way. Positive people give off positive energy. I like being around those people, which is why most everybody here is a positive energy person. They’re up tempo.”

And with a team you can rely on, you can provide the responsive, reliable service customers demand. That’s what makes Dwayne a smooth operator.