First AT-802F FRDS GEN III Firegates Installed On U.S. Air Tankers

A new Gen III FRDS firegate has received STC certification for installation on Air Tractor AT-802F airplanes.

Air Tractor, Inc. supplier Trotter Controls, with Air Tractor support, has received a Federal Aviation Administration Supplemental Type Certificate (STC) for its new all-electric, constant-flow Gen III Fire Response Dispersal System (FRDS) firegate for Air Tractor AT-802F and AT-802AF single engine airtankers. The Gen III firegate is a state-of-the-art, all-electric, lightweight next generation of firegate technology based on Air Tractor’s 25-year track record of success with over 350 firegate systems shipped worldwide.

Minnesota-based aerial firefighting company Dauntless Air recently received the first U.S. installation of the Gen III firegate on its AT-802F Fire Boss®, airframe N8522Q, during the course of the STC certification process. The company provided the airplane to Air Tractor as the test aircraft for certification activity.

Air Tractor President Jim Hirsch says he is pleased to have an aerial firefighting leader such as Dauntless Air as the owner of the first U.S.-installed Gen III firegate. “This is one of several aircraft component improvements available during our 2020 production cycle. We are thrilled to see it go into service in the U.S. market.”

Minnesota-based Fire Boss, LLC and New Mexico-based Aero Tech, Inc. have also installed FRDS Gen III systems in preparation for the 2020 fire season.

The FRDS Gen III firegate is the only computerized, constant-flow firegate for AT-802F aircraft with an FAA STC and FAA approved repair parts availability. The FRDS firegate will become part of the AT-802F Type Certificate later this year. Hirsch reports that new Air Tractor AT-802F aircraft will be equipped with the Gen III firegate beginning in early 2020.

The lightweight, all-electric firegate system provides 25 percent more flow, integrated foam injection control, integrated AFF tracking and ATU telemetry, and much simpler operation than previous systems.

The lightweight, all-electric firegate system provides 25 percent more flow, integrated foam injection control, integrated AFF tracking and ATU telemetry, and much simpler operation than previous systems.

Hirsch reports that new Air Tractor AT-802F aircraft are currently being delivered from the factory with FRDS Gen III systems installed as standard equipment.

On April 7, the U.S. Forest Service Interagency Airtanker Board (IAB) issued interim approval for Air Tractor AT-802F and Fire Boss operators to use the Gen III FRDS on their aircraft during the upcoming fire season, and through the end of September 2021. The IAB is working with Trotter and Air Tractor to complete the permanent approval.

The Gen III firegate can be retrofit to AT-802F airplanes equipped with Gen I and Gen II firegates, Hirsch added. “Fairings, vent doors, brackets, E-dump handle, and other items from earlier FRDS systems can be re-used. This commonality of parts is yet another example of Air Tractor’s long-standing customer support of our firegate systems.”

Four AT-802F airtankers equipped with Air Tractor’s new Gen III FRDS fire gate worked the recent bushfires in Australia, collectively amassing more than 500 flight hours of in-service use. Pilots from Fred Fahey Aerial Services, Kennedy Aviation, and Field Air report they are very pleased with the Gen III FRDS firegate performance. The firegate control unit is integrated with the DataVault telemetry and data acquisition system. It sends near real-time location and operational data telemetry to emergency operations managers via the Iridium satellite constellation. The DataVault meets or exceeds all NAFC and US Forest Service “proof of delivery” requirements.

Minnesota-based Dauntless Air provided Tanker 858 to Air Tractor as the test aircraft for STC certification of the Gen III FRDS.

Minnesota-based Dauntless Air provided Tanker 858 to Air Tractor as the test aircraft for STC certification of the Gen III FRDS.

According to Trotter Controls, the chief engineering partner for the Gen III FRDS firegate, aerial firefighting operators and government firefighting agencies report that the precise constant-flow operation, the very high flow rate, and the lighter weight of the system provide significant advantages over other firegate systems.

The extensive update to the FRDS system includes more than 270 lbs. (122 kg.) of weight reduction, all-electric operation, 25 percent more flow than the Gen II firegate, integrated foam injection control, optional integrated AFF tracking and ATU telemetry, and much simpler operation than previous systems.

The technical staff at Trotter Controls, Inc. developed the state-of-the-art gate box using 3D CAD modeling and many iterations of stress analysis to refine the lightweight design. The weight reduction was achieved by using aerospace materials, aerospace construction techniques, and by eliminating about 30% of the parts used in the Gen II FRDS design.

The controls and software team at Trotter Controls designed a system that meets Interagency Airtanker Board (IAB) tank performance specifications for Single Engine Air Tanker (SEAT) aircraft as well as Very Large Air Tankers (VLAT). The new controller and field proven DataVault are a simple and capable controls platform for the all-electric motor/gearbox that is used to position the fire doors during delivery operations. Additionally, the all-electric system streamlines troubleshooting and reduces maintenance as compared to hydraulics-based firegate systems.

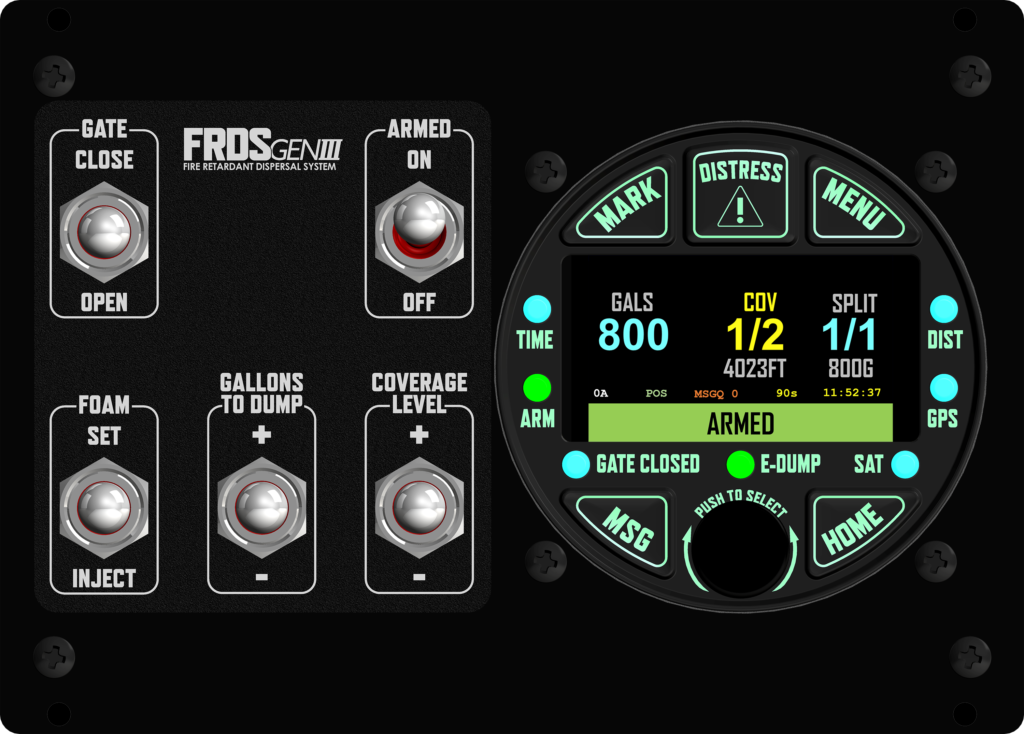

The firegate control unit provides excellent clarity and visibility in all lighting conditions.

A new modular pilot interface fits in the same space as the previous Gen II FRDS pilot interface unit and provides flexibility to mount switches wherever the operator prefers. The Pilot Interface display mounts in a standard 3-inch instrument gauge cutout and has a color OLED screen covered by anti-reflective glass and a back-lit silicone button overlay. The display provides excellent clarity and visibility in all lighting conditions.

The DataVault-based firegate controller can be purchased with or without built-in Automated Flight Following (AFF) tracking and Additional Telemetry Unit (ATU) data feed reporting. AFF-ATU tracking and telemetry reporting meets or exceeds Australia’s National Aerial Firefighting Centre (NAFC) and U.S. Forest Service (USFS) requirements.